Documentation for the latest CamBam release is available here...

Side Profiles

Side profiles are a method of producing 3D contours from 2D shapes, by creating radii and slopes.

Side profiles are created by manipulating the Side Profile composite property of the 2D Profile machining operation.

The files side profiles.cb and heart-shaped-box.cb, in the CamBam samples folder illustrate

various uses of side profile operations.

Properties

|

Method

|

None - Normal perpendicular sides.

Slope - Value contains the angle in degrees from vertical of the slope (or bevel).

Convex Radius - Value contains the radius of the convex contour.

Concave Radius - Value contains the radius of the concave contour.

|

|

Value

|

A value that controls the selected side profile method.

|

|

Adjust Cut Width

|

When False, the toolpaths will just follow the calculated profile. This is fine for a finishing pass,

but is not suitable for clearing stock.

Set Adjust Cut Width = True to machine all the stock layers above as well as on the profile.

This is useful for roughing operations.

|

The sign of the Value parameter is significant and reversing the sign will result in different effects.

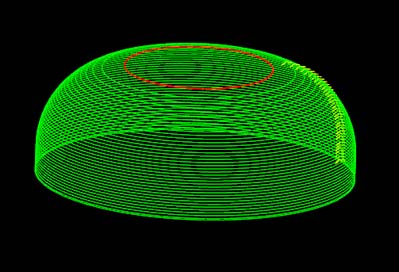

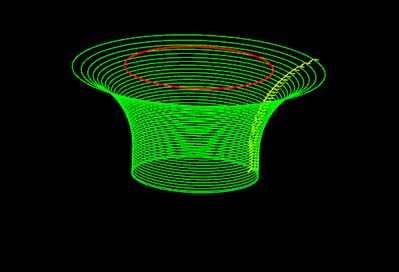

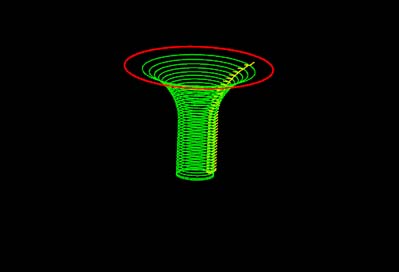

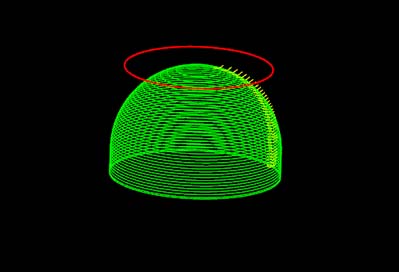

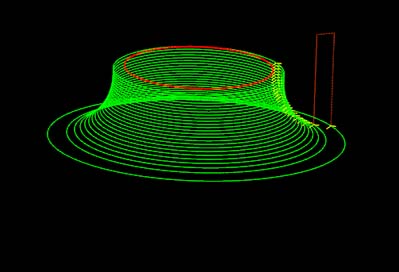

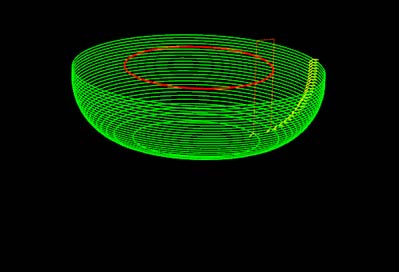

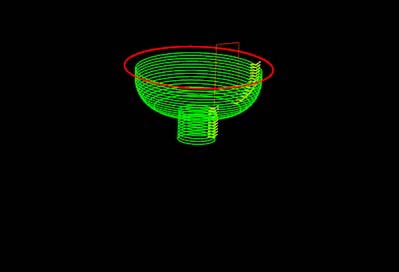

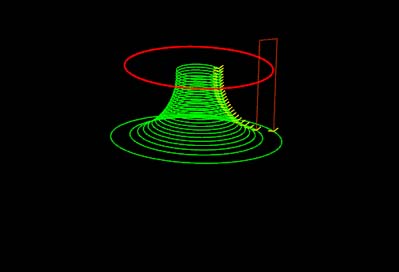

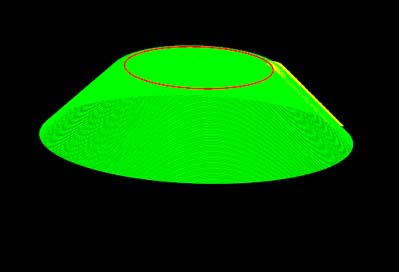

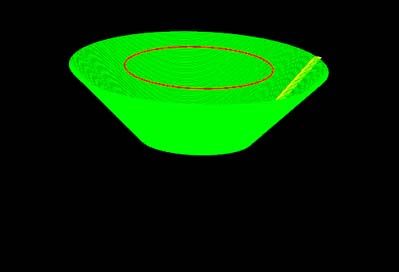

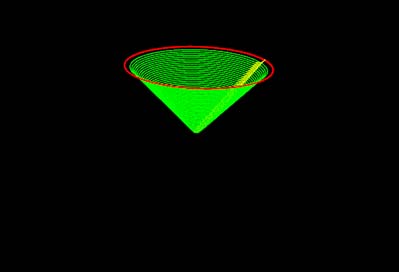

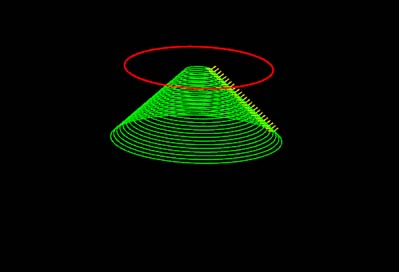

Below are some examples of various combinations of side profile methods, value signs and profile inside/outside settings.

These images were created from the side profiles.cb sample file.

Method=CovexRadius, Value=+Ve, Profile=Outside

|

Method=CovexRadius, Value=-Ve, Profile=Outside

|

Method=CovexRadius, Value=+Ve, Profile=Inside

|

Method=CovexRadius, Value=-Ve, Profile=Inside

|

Method=ConcaveRadius, Value=+Ve, Profile=Outside

|

Method=ConcaveRadius, Value=-Ve, Profile=Outside

|

Method=ConcaveRadius, Value=+Ve, Profile=Inside

|

Method=ConcaveRadius, Value=-Ve, Profile=Inside

|

Method=Slope, Value=+Ve, Profile=Outside

|

Method=Slope, Value=-Ve, Profile=Outside

|

Method=Slope, Value=+Ve, Profile=Inside

|

Method=Slope, Value=-Ve, Profile=Inside

|